- Produkty

- Řídicí systém

- Zprávy & Média

- Společnost

- Kontakt

- Produktselektor

The automation solution from HURCO®: The ProCobots® robotic arms

Efficiency through automation

The automation of CNC machines aims to increase productivity, shorten loading times, reduce the error rate and downtime and thus improve overall efficiency. Automatic loading processes using robots enable personnel capacities to be used more efficiently, for example to prepare new production orders while the current order is processed automatically.

Advantages of the ProCobot® robot arm

- The HURCO® Automation Job Manager software is fully integrated into the CNC control of the HURCO® machines. We have developed the control software in such a way that programming is not carried out on the robot, but directly on the control system via the HURCO® Automation Job Manager software. This makes your automated CNC lathe or milling machine with CNC robot arm super smart and ready for production super fast.

- The ProCobots® robot is an attractive solution to the current shortage of skilled workers.

- By using the robot, more turnover can be generated with the same number of employees.

- Thanks to the extended machine running times, the ProCobots® ProFeeder can potentially generate €120,000* in turnover.

Benefit from the advantages of our ProCobots® automation solution. We support you in automating your CNC machining center for smart manufacturing in no time at all!

* based on hourly machine rate: EUR 50.00

Machine running times: Mon - Fri 06:00 - 18:00, Sat 07:00 - 13:00

Machine downtime of 12 hours corresponds to approx. 600.00 EUR / day

For a 5-day week, this is 3,000.00 EUR. That is 120,000.00 EUR per year

One automation solution, many possibilities

The ProCobots® robot arm is compatible with a wide range of our machines. From compact 3-axis milling machines and powerful 5-axis machining centers to flexible lathes for complete machining - our automation solution enables an even more efficient production workflow on each model.

Automation you can touch

In cooperation with our regional sales partners, we organize HURCO® in-house exhibitions. Throughout Germany and beyond, we will be demonstrating at first hand how ProCobots® work on your machine and make the production process more efficient and simpler.

The supporting program also offers the opportunity to have the ProFeeder demonstrated and to take part in practical workshops in your area to get a feel for the operation live and in color.

Invest once, benefit twice

In addition to the annual sales potential, you benefit from an attractive introductory discount when automating your HURCO® machining center with ProCobots®. Our sales staff will put together a customized automation offer for you and your CNC machine to make your entry into autonomous CNC production cost-efficient.

What is automation?

Automation describes the use of digitalized processes and mechanical technologies to increase efficiency and productivity when manufacturing and machining workpieces or tools.

Automation can take place via the software of a CNC-controlled machine tool. Once the machining program has been initially programmed in dialog or via G-code, including cutting data, tool changes and other parameters, even complex parts can be manufactured automatically.

Automated systems with hardware elements, such as CNC robot arms, can be used to optimize the material flow. In this way, raw materials are automatically loaded into the machine and finished parts are unloaded.

What are the reasons for automation?

In order to secure a competitive edge as a company in the respective industry, more and more companies are relying on the automation of their machines, for example through robotics. CNC robotics modules, such as CNC robot arms, allow specific tasks in the production process to be carried out autonomously. High productivity and flexibility can be achieved by automatically loading a milling machine or lathe using a CNC-controlled robot.

Automation solutions and robots are playing an increasingly important role for companies, particularly in industry and production, due to the current shortage of skilled workers.

HURCO ProCobots® - The solution for automation at the highest level

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

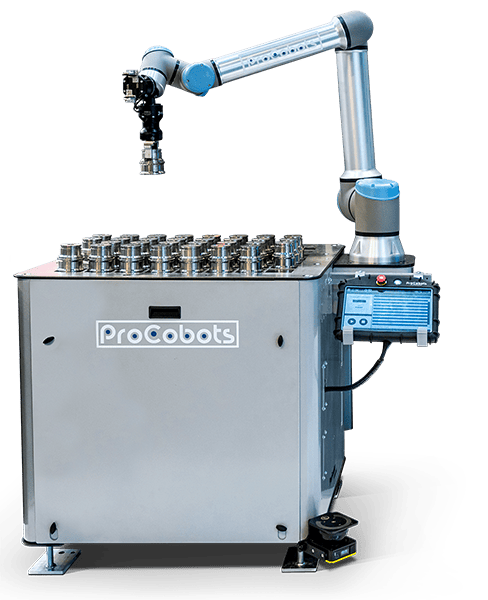

More InformationThe standard package: Loading with a system

The automation package from HURCO® is the perfect solution to increase the efficiency of your CNC machining and manufacturing. This is because the ProCobots® robotic arm enables automatic loading of your CNC machine. Switching to different machines is easy, saves time and allows flexible production of series on different machines . The investment also pays off quickly: usually the payback period of an automation project in production is less than one year.

Reduce idle time, maximize profit

By reducing machine downtime, companies can generate up to an additional 120,000.00 euros in potential sales annually. This calculation is based on a machine hourly rate of 50.00 euros and an average machine running time of 11 hours per day for six working days. This means you can mill and turn around the clock.

Equipment at a glance

- Automatic doors with additional manual control unit for manual operation.

- Two adaptive grippers: 50 mm stroke, for parts up to 2,5 kg (UR10e)

- Schunk gripper: for parts up to 15 kg (UR20 | UR30)

- Cleaning nozzle frees clamping and component from chips by air pressure

- Cobot solution: safety through a cutting disc and a safety laser scanner

Do you have any questions about our standard package? Feel free to contact us via our contact form - our specialists with years of experience and in-depth know-how will be happy to assist you with your request and provide you with further information.

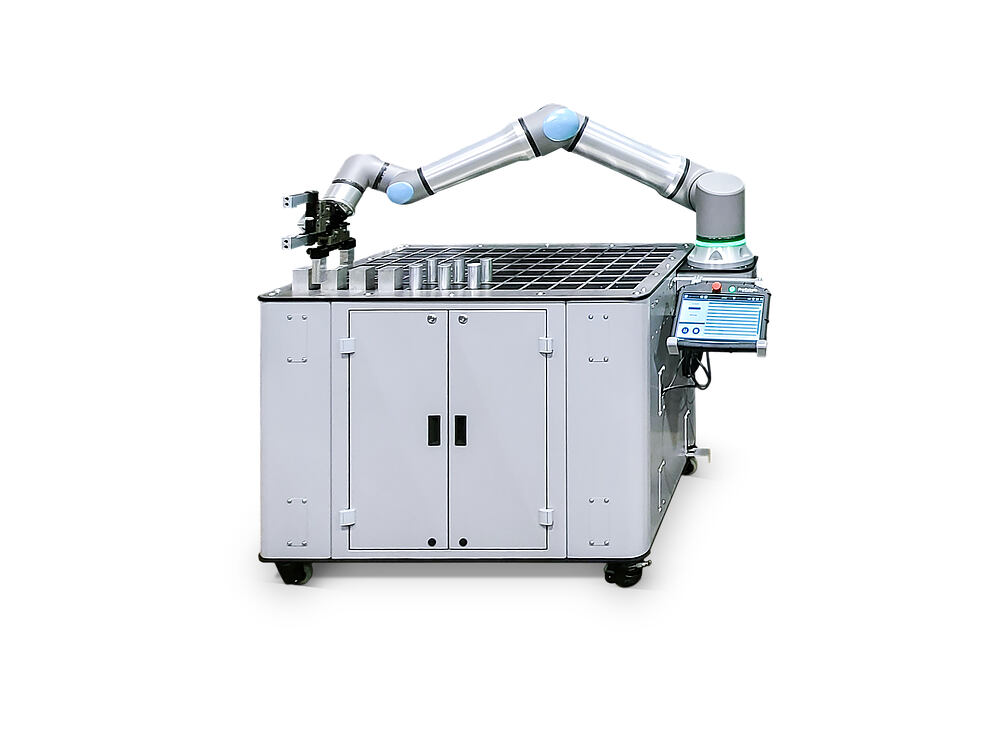

ProCobots® operating and loading systems

By means of a CNC robot arm, the ProCobots® loading systems assist your employees in the machining of tools or components. This means that the robot takes over the loading of the machine. Automatic loading frees up personnel resources that can be used elsewhere for complex work steps.

Robotic arms

The robot arms from Universal Robots support you in loading your machine tools. The ProFeeder Cart and ProFeeder Tray feature the UR10e CNC robot arm, while the ProFeeder EasyDesk loading systems are equipped with either the UR20 or UR30.

Our automation solution at a glance

Efficiency through automation

From hardware and software to installation and training - you get the automation solution from HURCO® in an all-round, worry-free package: The ProCobots® hardware consists of the ProFeeder Cart and the ProFeeder Table, each with a UR10e CNC robot arm. The Automation Job Manager is fully integrated into the MAX®5 control system. As a result, no programming is required on the robot screen. The Automation Job Manager is simple in design and operation can be learned quickly.

When you purchase a ProCobots® robotic arm from HURCO®, you not only get the product, but also the comprehensive service in the usual HURCO® quality. Delivery and installation are included. Instruction by our experienced automation experts is optionally available so that you can successfully implement your project and work precisely with your new system. We look forward to hearing from you.